|

| April 26, 2022 | Volume 18 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New NASA alloy built to handle extremes

This turbine engine combustor (fuel-air mixer) was 3D printed at NASA Glenn and is one example of a challenging component that can benefit from applying the new GRX-810 alloys. [Credits: NASA]

By Diana Fitzgerald, NASA's Langley Research Center

NASA innovators recently developed a new metal alloy using a 3D-printing process (laser powder bed fusion) that dramatically improves the strength and durability of the components and parts used in aviation and space exploration, resulting in better and longer-lasting performance.

NASA Alloy GRX-810, an oxide dispersion strengthened (ODS) alloy, can endure temperatures over 2,000 F, is more malleable, and can survive more than 1,000 times longer than existing state-of-the-art alloys (Ni-based super alloys). These new alloys (made using specially coated metal powder) can be used to build aerospace parts for high-temperature applications, like those inside aircraft and rocket engines, because ODS alloys can withstand harsher conditions before reaching their breaking point.

"The nanoscale oxide particles convey the incredible performance benefits of this alloy," said Dale Hopkins, deputy project manager of NASA's Transformational Tools and Technologies project.

It's challenging and expensive to produce ODS alloys for these extreme environments. To develop NASA Alloy GRX-810, agency researchers used computational models to determine the alloy's composition. The team then leveraged 3D printing to uniformly disperse nanoscale oxides throughout the alloy, which provides improved high-temperature properties and durable performance. This manufacturing process is more efficient, cost effective, and cleaner than conventional manufacturing methods.

[Designfax Editor's Note: What is notable at this point is the final alloy is made while the part is being produced (3D printed). The coated powder mix comes together as the final alloy through the 3D-printing (laser powder bed fusion) process. The medium-entropy alloy is made of oxide dispersion strengthened nickel/cobalt/chromium or NiCoCr. The oxide agent is yttrium oxide or Y2O3. The final product is called ODS-NiCoCr.]

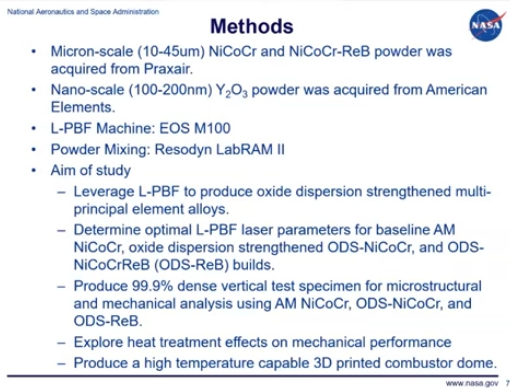

You can get an idea of the composition of the Alloy GRX-810 in this screenshot of the NASA presentation that is available in full below.

These alloys have major implications for the future of sustainable flight. For example, when used in a jet engine, the alloy's higher temperature and increased durability capability translates into reduced fuel burn and lower operating and maintenance costs.

This alloy also affords engine part designers new flexibilities like lighter materials paired with vast performance improvements. Designers can now contemplate tradeoffs they couldn't consider before, without sacrificing performance.

Breakthrough performance is a revolution in materials development

NASA's new alloys deliver enhanced mechanical properties at extreme temperatures. At 2,000 F, GRX-810 shows remarkable performance improvements over current state-of-the-art alloys including:

- Twice the strength to resist fracturing;

- Three-and-a-half times the flexibility to stretch/bend prior to fracturing; and

- More than 1,000 times the durability under stress at high temperatures.

"This breakthrough is revolutionary for materials development. New types of stronger and more lightweight materials play a key role as NASA aims to change the future of flight," said Hopkins. "Previously, an increase in tensile strength usually lowered a material's ability to stretch and bend before breaking, which is why our new alloy is remarkable."

Coupling additive manufacturing with material modeling

The team applied thermodynamic modeling and leveraged 3D printing to develop the new high-temperature alloy.

"Applying these two processes has drastically accelerated the rate of our materials development. We can now produce new materials faster and with better performance than before," said Tim Smith, a material research scientist at NASA's Glenn Research Center in Cleveland and one of the inventors of this new alloy.

"What used to take years through a trial-and-error process now takes a matter of weeks or months to make discoveries," added Hopkins.

Webinar: Learn all the fine details: NASA's additive manufacturing alloys for high-temperature applications (video run time = ~30 min.).

Using thermodynamic modeling, one of many computational tools discussed within the NASA 2040 Vision Study, the team discovered the optimal alloy composition after only 30 simulations.

This modeling tool produces results in much less time and with lower costs than traditional trial-and-error processes. The tool also avoids dead ends by showing researchers not just what metal types to incorporate but how much of each element to infuse into the composition. "The performance of this alloy clearly demonstrates the modeling tool's maturity and ability to produce significant results," said Steve Arnold, materials and structures technical discipline lead at NASA Glenn.

Published April 2022

Rate this article

View our terms of use and privacy policy